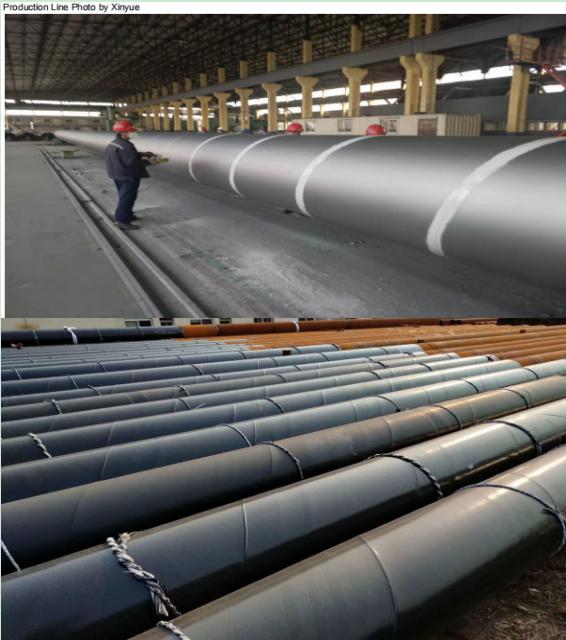

One-stop supplier of steel pipe production and anti-corrosion processing

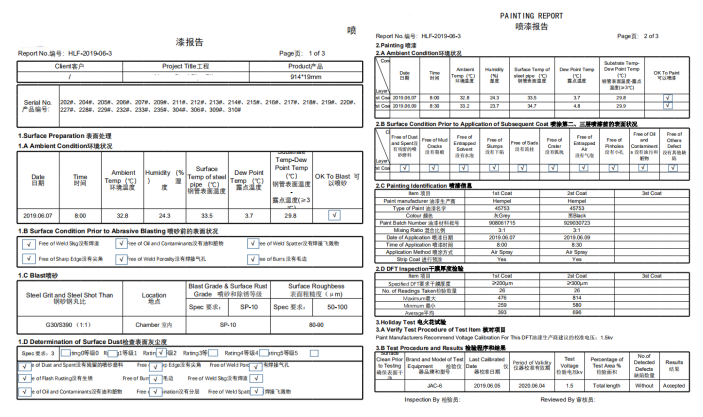

Jun. 24, 2020

According to statistics, the annual global steel pipe corrosion losses are as high as 500 billion US dollars. Corrosion-resistant steel pipes can effectively prevent or slow down corrosion and extend the service life of steel pipes, reducing the running cost of steel pipes.

With the expansion of business scope and the different needs of global terminal projects, the orders of anti-corrosion steel pipes that our company has undertaken are also more and more diversified. Common anti-corrosion mainly include hot-dip galvanizing, epoxy coal pitch, epoxy resin paint, epoxy coal Tar, epoxy powder, polyethylene, polypropylene, polyurethane water pipeline anti-corrosion non-toxic coating anti-corrosion polymer coating, anti-corrosion steel pipe wall mortar anti-corrosion, etc.

In order to ensure product quality, Xinyue has implemented strict internal quality control standards from entering the factory to producing and leaving the factory:

1. Choose high-quality domestic and foreign brand spraying materials. Clean and derust the pipe surface with sa 2.5/sa3.0 grade

2. Generally completed in the workshop: environmental conditions temperature and humidity must meet the construction requirements of paint spraying, especially away from moisture. Fully cured;

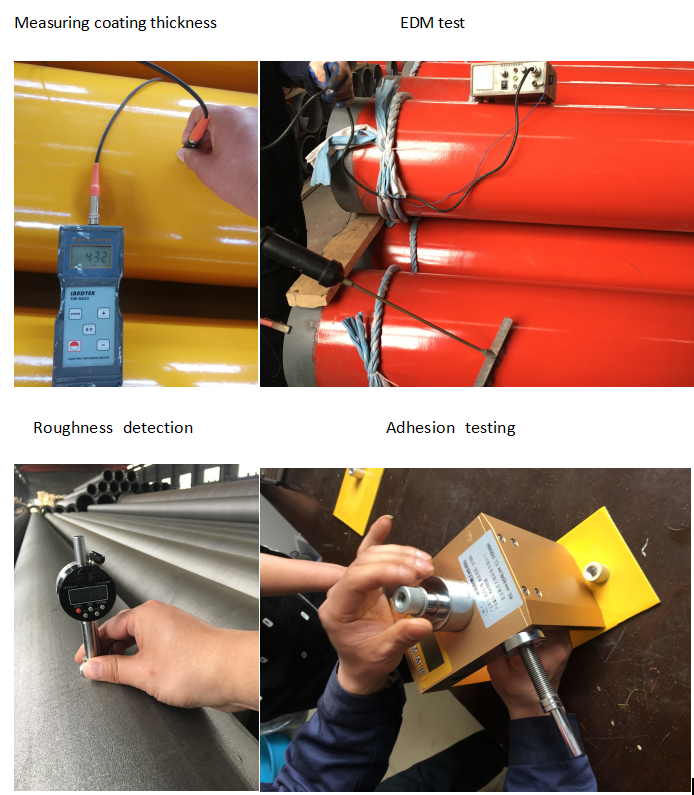

3. After the anti-corrosion work is completed, relevant tests such as thickness measurement, electrical sparking, roughness, stretching, and adhesion will be carried out to ensure that the standard requirements are strictly implemented.

4. Product protection during stacking and transportation.

EN10219 S355JR, S355JOH SSAW Steel Pipe with C9 interlock and sheet piles

Atmospheric zone: Zinc rich +Epoxy+Polyurethane

Splash zone+Submerged zone:Zinc rich + high solid epoxy

Buried zone:Epoxy

2600 TONS coated steel pipe for drink water project

Coating:External 3LPE Coating, Thickness 4mm, Blue Color, External SA2.5 Blasting Internal Coating: Internally Liquid Food Grade Epoxy with WRAS Certification (400 microns , White Color), Internal SA2.5 Blasting in accordance with ISO8501-01/SIS 055900 standards .

Hempel Coated pile pipe for marine structures( Coating: Apply one stripe coat (grey) of HEMPEL with a dry film thickness of 200 microns over all weld seams, bolts, sharp objects,Primer coat: HEMPEL epoxy applied to a minimum dry film thickness of 200 microns.Finish coat:HEMPEL epoxy applied to a minimum dry film thickness of 300 microns.

Corrosion-resistant steel pipe is corrosion-resistant, non-leakage, high toughness, has excellent flexibility, has good resistance to scratches, has good resistance to rapid crack transmission, and can have a life of more than 50 years in an environment of 60 degrees Celsius or more . It is widely used in petroleum and natural gas transportation; heating, water supply, drainage pipelines, bridges, high-rise building foundation piling, coal water slurry transmission lines, etc. For more anti-corrosion details, please contact us!

Written by Phebe