Marine Pile Project From Regular Australia Client

Sep. 04, 2020

Xinyue Steel Group was awarded by a marine pile project from regular OZ client on July 2020, with specification: API 5L PSL1 X52 914.4*20MM/ 1300*30MM, length 8-13meters, 530tons in total, supplement piles for on-going project, which got below detail requirements:

Bare (No Protective Coating), New Material, Beveled End With End Protectors

Manufacturing of 100% NDT /NDE and 100% Hydraulic (Hydrostatic Test) & 100% X-Ray Test, Dimensional Check

SSAW (Spiral Submerged Arc Welding) STEEL PILE CASINGS

Specification: API 5L X52 PSL 1

All welding shall be according to ASME IX

The supply and manufacturer is to be in compliance to terms & conditions of API pecification 5L – Forty-Sixth Edition

Pipe Marking: At both ends of the pipe (inside or outside) to be provided with order as per end customer requirement. Each Pipe is to be numbered and identified with Raw Material Heat/Batch Number, Specification, Grade, length, sizes, and wall thickness

Two samples from each heat number of raw materials should be taken at the pipe making mill at the witness of SGS prior to fabrication start, one for SGS lab test and one for mill standard test ( no manufacturing is allowed prior to TPI sampling, checking of all raw materials, mill test certificate (MTC) and requested manufacturing documents i.e. ITP, WPS, PQR, etc.)

SGS Receive and audit Pipe Mill all QA manufacturing & fabrication including:

*Witness lab test for mechanical properties at pipe mill lab (or at an arranged lab) lab to be CNAS approved;

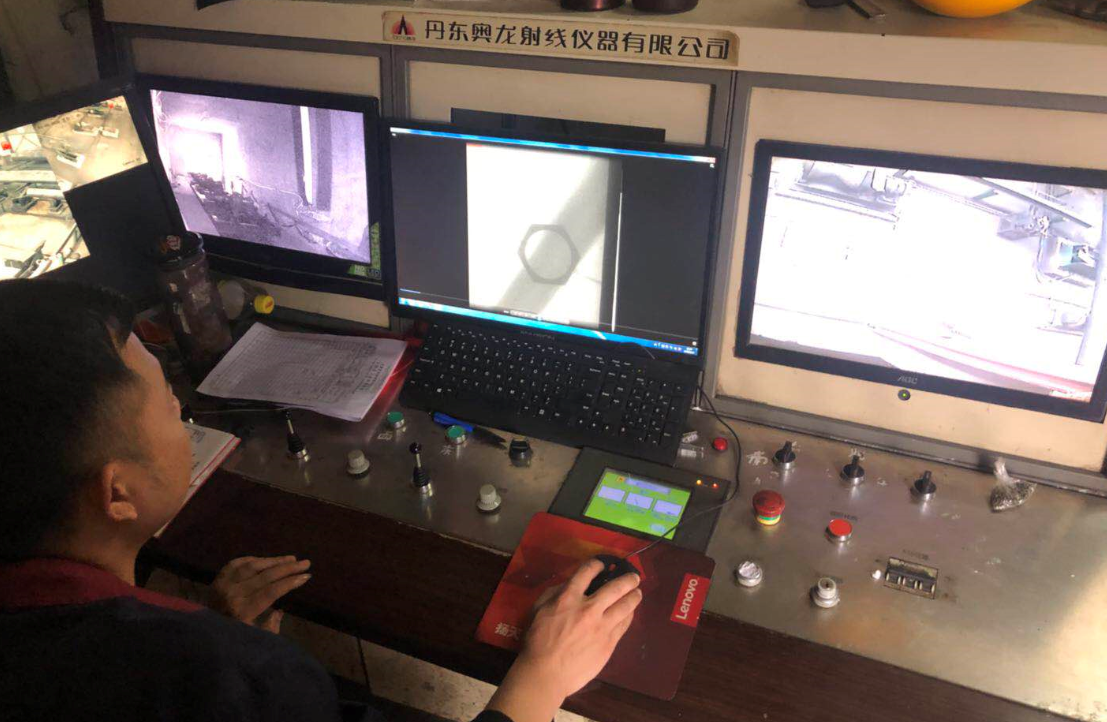

*Witness of in-line manufacturing, X-Ray, UT & Hydrostatic tests, Dimensional check of the order;

* Inspect and Test 100% of the welds UT & X-ray (all welds shall be according to ASME IX and to annex E of API 5L)

*Dimensional check of 100% of the order - length, diameter, wall thickness, straightness,

tolerance, etc. as per standard conducted in accordance with API 5L PSLI

*Check rework - welds and repairs of all products that fail

*Receive and review all manufacturing production report and tests of each pipes daily from pipe mill.

*Witness loading of pipes in containers, lashing and tie down, record container number, pipe

numbers, quantity of each size of pipes, take photos.

*Provide Lab Test Report of materials - mechanical tests of yield, tensile elongation & charpy and any other tests as required i.e. chemical tests.

*Inspection, Testing and QA Report at Pipe Making Factory

We already have received test report for raw material from SGS test lab that: all raw material samples have passed mechanical properties and chemical composition tests, all datas are qualified.

The TPI inspector also issued his witness & inspection report: that’s all pipes have passed 100% hydro test, X-ray test, Ultrasonic test and dimension inspection by SGS. All data and results show that our products are 100% compliant to API 5L.

All piles will be sent to port once received notification about the shipment from client and will be delivered to project site as project schedule required.

Tianjin Xinyue Steel Group, you reliable steel partner.

Written by Nicole