Anti-corrosion information

Sep. 11, 2019

Nowadays the requirements to pipeline anti-corrosion is more and more high level, meanwhile the anti-corrosion technology is also more and more advanced.

There are around ten kinds of types:

1. Cement Mortar Lining Protection,

2. Liquid Epoxy coating,

3. Fusion Bond Epoxy,

4. Bitumen coating,

5. 3 layers Polyethylene/Polypropylene,

6. Polyurethene insulated Coating,

7. Coal Tar Epoxy,

8. Glassflake Epoxy,

9. Polyurethane Coating

Anti-corrosion work flow:

First,Surface treatment, Second,Coating work, Third, Coating Inspection.

In order to make the coating be more strong on the pipe, need to do the surface treatment: cleaning, derusting,pickling and sandblast, it main to remove the rust, mill scale, dirt ...etc.

Then its coating procedure, there are five methods: automatic machine, air spray, airless spray, brush and roller .

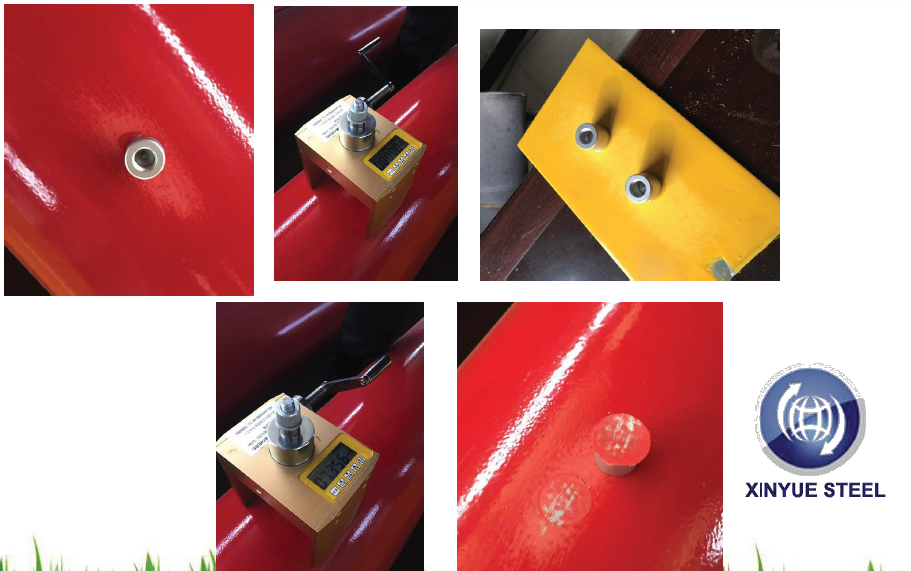

At last will be the Coating Inspection, also have surface checking, coating thickness,holiday detection,Adhesion Inspection,Cathodic dis-bonding test.

After everything qualified, then could packed and deliver to clients.

Xinyue insist on building the best quality brand and will keep going ! Welcome to your enquiry !

Written by Sanny